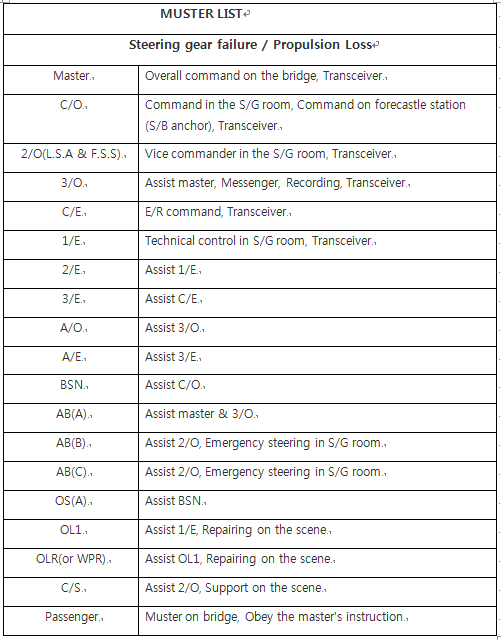

1. International Regulations for Steering Gear

These require either that cargo vessels in general must have an auxiliary steering gear as a backup for the main gear (and that if the rudder stock is over 356mm (14 in.) in diameter this second gear must be power operated) or that power units and connections are duplicated. ‘Power unit’ described the pump and motor or equivalent. Short-circuit protection only is to be provided for electric motors and power circuits. There must be two widely separated power circuits from the main switchboard, one of which may pass through the emergency switchboard. A rudder indicator must be fitted on the bridge.

The steering gear must be able to meet the performance requirement of being above to move the rudder from 35° on one side to 35° on the other with 28 seconds being allowed for that part of the movement from the 35° extreme to 30° at the other. Main and auxiliary gears are required or there may be duplication of power units.

Design of the system should be such that a single failure in its piping or one power unit (pump and motor or equivalent) will not leave the steering gear inoperable. The emergency supply is to be automatically connected within 45 seconds of main supply failure and must be capable of continuous operation for 30 minutes.

The standard of performance when the equipment is working on the alternative supply is that at least it will move the rudder from 15° on one side to 15° on the other in 60 seconds. It must be capable of this with the ship at its deepest draught and running ahead at one-half the maximum ahead service speed or 7 knots, whichever is greater.

Regulations require that the steering gear compartment must be readily accessible and arrangements made to ensure working access to the machinery and controls. This must include handrails and gratings (or other non-slip surfaces) to make safe working conditions in case there is a leak of hydraulic oil. In order to operate the steering gear in its best condition at all times, it must be maintained and make inspection in accordance with maintenance procedures.

2. Management steering gear

1) Steering pump shall be operating 30 min. – 1 hour in advance of its use.

2) When an abnormal noise is heard, immediately check the cause of the noise.

3) Oil tank level shall be kept higher than 80%.

4) Confirm the rudder indicator is in [0] position before starting. When the steering pump is required to operate while being on berth, venting air is essential.

3. OPERATION

1) Start by pushing No.1 or No.2 Operation Button in the operating panels of the wheel house or steering gear room.

2) Confirm the system levels of automatic steering gears are matching between No.1 and No.2 units.

3) Either when entering/departing a port, sailing under a rough sea or if necessary, operates No.1 and No.2 units together simultaneously.

4. STOPPING

1) Set Rudder Indicator to [0].

2) Turn the system level of steering gear to [STOP] position.

3) Press [STOP] button at wheel house or the steering gear room.

4) Pressing [BUZZER STOP] button stops the buzzer sound.

5. EMERGENCY STEERING

Emergency steering is used when Manual Handle [when AUTO /MANUAL /NFU modes are in trouble. The following procedures should be made before emergency steering.

Procedures (if steering pump is still running)

At the wheelhouse,

1) Set the steering mode to “HAND” position

2) Set auto pilot system to “OFF” position

3) Switch off steering gear motor (at the bridge steering alarm panel).

At the steering gear room,

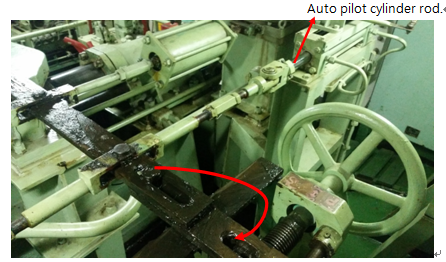

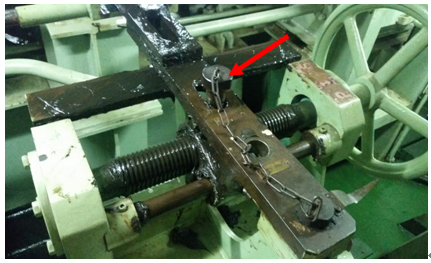

1. Pull out the lock pin which connects the floating lever and auto pilot cylinder rod.

2. Put the lock pin in position which connects the trick wheel.

3. Operate the steering gear by handling the trick wheel by turning port or starboard until the rudder reaches the command rudder angle.

Procedures (if steering pumps is fail to run)

At the wheelhouse,

1) Set the steering mode to “HAND” position

2) Set auto pilot system to “OFF” position

3) Switch off steering gear motor (at the bridge steering alarm panel).

At the steering gear room,

1) Set overload device (electrical power)to “OFF” position(at autopilot control power box)

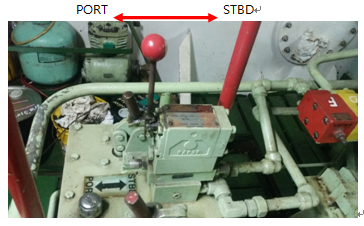

2) Open and close the stop valve ( A,B,C,D close and E,F open)

3) Operate the steering gear by using the hand lever

The heading can be checked by repeater gyro & rudder position by rudder indicator

6. Steering Gear Testing, Drills and Examinations

Under International (IMO, SOLAS) regulations the Master must , within 12 hours before each departure (except for ships on short voyages on which the tests must be carried out weekly) ensure that the steering gear is checked and tested in order to be sure that it is working satisfactorily.

`The test procedure shall include, where applicable, the operation of the following:

- The main steering gear;

- the auxiliary gear;

- the remote steering gear control systems;

- the steering positions located on the navigating bridge;

- the emergency power supply;

- the rudder angle indicators in relating to the actual position of the rudder;

- the remote steering gear control system power failure alarms;

- the steering gear power unit failure alarms; and

- The automatic isolating arrangement and other automatic equipment required for steering gear.

The checks and tests shall include:

- the full movement of the rudder according to the required capabilities of the steering gear;

- a visual inspection of the steering gear and its connecting linkage; and

- The operation of the means of communication between the navigating bridge and the steering gear compartment.

Prior to the tests, the deck department should be informed and it should be verified that there are no obstructions in way of the rudder. The oil level in the supply tank should be checked and topped-up to about 75% of its capacity and where arrangements are provided for testing low level alarms these should be operated.

The regulations require that emergency steering gear drills be carried out at least every three months. These drills must include direct control from the steering gear compartment, the communications procedure with the navigation bridge and, where applicable, the operation of alternative power supplies.

Simple operating instructions with a block diagram showing the change-over procedures for remote steering gear control systems and steering gear power units must be permanently displayed on the navigation bridge and in the steering gear compartment.

On vessels operating a checklist system, the testing of the steering gears will be covered on the “Preparation for Departure” checklists. On vessels with two steering gears, on standby, both are normally running to give a faster rudder response.

댓글